|

4/29/2023 Exploring the Different Styles of Jet Pumps for Watercraft: A Comprehensive GuideRead NowJet pumps are an essential component of watercraft propulsion systems. They work by drawing in water through an intake, compressing it, and then expelling it through a nozzle to create thrust. There are several different styles of jet pumps, each with its own unique characteristics and advantages. In this blog post, we'll explore some of the most common styles of jet pumps used in watercraft.

In conclusion, jet pumps come in various styles, each with its unique features and applications. Axial-flow jet pumps are the most common in personal watercraft, mixed-flow jet pumps are popular in larger watercraft such as jet boats, radial-flow jet pumps are known for their high efficiency and ability to handle high flow rates, venturi jet pumps are specialized for high suction applications, and ejector jet pumps are commonly used in industrial applications. Understanding the different styles of jet pumps can help you choose the best option for your watercraft's specific needs. Bobby Boop Impellers.com

0 Comments

Although they may sound alike, impellers and propellers have distinct purposes and functions. Despite being employed to propel a boat, they operate in fundamentally different ways. A propeller functions as a fan, pushing against fluid to generate forward movement by converting rotational force into linear motion. On the other hand, an impeller serves as a rotor that is typically integrated into a pump and generates a suction force, drawing fluid into a vehicle or engine. To gain a better understanding of these elements and their functions, let's delve deeper into each of them. Impeller In simple terms, an impeller is a rotor component that generates a suction force within a pump system. In the case of a boat, the impeller is composed of a series of flexible rubber vanes attached to a central hub, which rotates around an axis inside a stainless-steel liner housed within the pump. This mechanism pumps cold water into the boat's engine to cool it down while under load, and is also used to bring water from outside the boat into the plumbing system. The impeller features an inlet that allows water to flow into the boat, and the rubber vanes propel the fluid through the inlet. As the rotating component of a centrifugal pump, the impeller drives fluid away from the center of rotation, transferring energy from the pump to the water and creating velocity that propels the water outward from the pressurized pump. The impeller can be likened to an early and rudimentary version of the Archimedes screw. Impellers can be classified into three different categories based on solidity: high, medium, and low. High solidity impellers feature large, square-shaped blades that are primarily used for gas dispersion and blending of high or medium viscosity fluids. The specific design and size of these blades prevent gas from bypassing them, which could easily occur if the blades were narrower. In contrast, low solidity impellers have much thinner blades than high solidity ones and are typically employed for blending low viscosity fluids and solid suspension. Medium solidity impellers fall somewhere between high and low solidity types. Propeller A propeller can be thought of as a type of fan that generates thrust by pushing fluid away from it, converting rotational motion into linear motion (extrinsic). In the context of a boat, the propeller works by creating thrust and generating power to propel the boat forward. Propellers typically have three or four blades that rotate around an axis, driving the boat through the water. As the blades rotate, the water pressure behind each blade increases, propelling the boat forward. The angle at which the blades protrude from the hub allows water to flow from the front of the propeller to the rear without pushing water to the sides. Generally, increasing the number of blades on a propeller can enhance the power generated by the vehicle and reduce drag. The thrust generated by propellers can be explained by either Bernoulli's theorem or Newton's laws of motion. Cavitation is a common problem in centrifugal pumps that can cause damage to the pump and decrease its efficiency. Cavitation occurs when the pressure in a fluid drops below the vapor pressure of the liquid, causing bubbles to form and then collapse. This can lead to erosion, noise, vibration, and reduced pump performance. In this post, we'll discuss the common causes of cavitation in centrifugal pumps and how to prevent it.

Damaged Impeller A damaged impeller is one of the most common causes of cavitation. The impeller is the rotating part of the pump that moves the fluid. When the impeller is damaged, it can create turbulence and low-pressure areas that lead to cavitation. To prevent this, it is important to regularly inspect and maintain the impeller. Bad Wear Ring The wear ring is a stationary part of the pump that surrounds the impeller. It helps to maintain the proper clearance between the impeller and the pump housing. A bad wear ring can cause cavitation by allowing too much fluid to leak back into the inlet side of the impeller, creating a low-pressure area and leading to cavitation. To prevent this, the wear ring should be regularly inspected and replaced as needed. Bad Driveline Seal The driveline seal is the seal between the pump and the motor. A bad driveline seal can allow air to enter the pump, which can cause cavitation. To prevent this, the driveline seal should be regularly inspected and replaced as needed. Bad Pump Seal The pump seal is the seal that prevents the fluid from leaking out of the pump. A leaking pump seal can allow air to enter the pump, leading to cavitation. To prevent this, the pump seal should be regularly inspected and replaced as needed. In conclusion, cavitation can be caused by a damaged impeller, bad wear ring, bad driveline seal, and pump seal. To prevent cavitation, it is important to regularly inspect and maintain these components. By doing so, you can improve the efficiency of your pump and extend its lifespan. If you are experiencing cavitation in your centrifugal pump, contact Impellers.com for expert advice and pump solutions. Our team of engineers can help you diagnose and solve any pump problems you may be experiencing. Bobby Boop Impellers.com As a company that specializes in repairing damaged leading edge impellers, we understand the importance of ensuring that your equipment is operating at its best. When your impellers become damaged, it can cause a range of issues, from reduced efficiency to complete equipment failure. That's why we offer a comprehensive solution to help you get your equipment back up and running as quickly as possible. Our team of experts has years of experience in repairing damaged impellers, and we understand the intricacies involved in ensuring that your equipment is working correctly. We use only the highest quality materials and state-of-the-art technology to repair your impellers, ensuring that they perform at their best once they are back in service.  Damaged Leading Edge Impellers Fix Damaged Leading Edge Impellers Fix A common cause of damage to leading edge impellers is impact damage from rocks and debris. This can occur in a range of environments, including in marine and industrial settings. When your impellers are damaged in this way, it can cause significant problems, including reduced efficiency and damage to other parts of your equipment. At our company, we have extensive experience in repairing impellers that have been damaged by rocks and debris. Our team of experts uses advanced techniques to assess the extent of the damage and determine the best approach to repairing it. We understand that time is of the essence when it comes to equipment repairs, and we work quickly and efficiently to get your impellers back in working order as soon as possible. In addition to repairing the damage caused by rocks and debris, we also take steps to prevent future damage. This can include the installation of protective coatings or liners to help prevent impact damage from occurring again in the future. By taking a proactive approach to maintenance, we can help ensure that your equipment operates at peak efficiency for years to come. Whether your impellers have been damaged by erosion, impact damage, or other factors, our team is here to help. We specialize in repairing damaged leading edge impellers and can provide the high-quality service and support that you need to keep your equipment operating at its best. So if you're experiencing issues with your impellers, don't hesitate to get in touch with us today. We're here to help, and we look forward to serving you. If you're a Sea-Doo owner, you know how important the impeller is to your personal watercraft's performance. The impeller is a vital component that transfers the engine's power to the water and propels the Sea-Doo forward. Over time, however, the impeller can become damaged or worn, leading to decreased performance and efficiency.

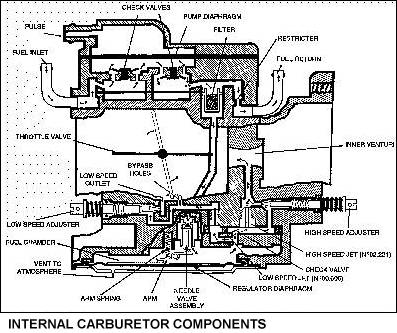

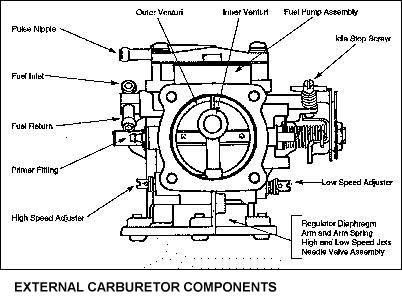

At our business, we specialize in repairing Sea-Doo Spark impellers. We understand the importance of a well-functioning impeller, which is why we use only the highest-quality materials and techniques to restore your impeller to its original condition. Our experienced technicians are skilled in diagnosing impeller damage and providing the necessary repairs to ensure optimal performance. In addition to repairs, we also offer impeller polishing services. Our state-of-the-art polishing equipment is capable of producing a mirror finish that not only looks great but also reduces drag and improves performance. A polished impeller creates less friction with the water, allowing for smoother and faster acceleration. When you bring your Sea-Doo Spark impeller to us for repairs, you can expect a thorough inspection and diagnosis of any damage or wear. Our technicians will use specialized tools to carefully remove any dents, nicks, or scratches from the impeller's surface. We will also replace any worn or damaged parts with high-quality OEM parts to ensure long-lasting performance. Once the repairs are complete, we will polish the impeller to a mirror finish. This process involves using specialized machinery to remove any imperfections in the impeller's surface and create a smooth, shiny finish. The result is an impeller that not only looks great but also performs at its best. At our business, we are committed to providing the highest-quality Sea-Doo Spark impeller repair and polishing services. Whether you need minor repairs or a complete impeller overhaul, our experienced technicians have the skills and expertise to get the job done right. Contact us today to learn more about our services and schedule your impeller repair and polishing appointment. Carburetors are important for controlling the speed of engines. They are responsible for mixing and metering the air/fuel mixture at an ideal ratio for different throttle positions, engine loads, or RPMs. To tune the carburetor, you must understand the pressure changes that impact air and fuel flow in the intake tract. This article is part of a three-part series on carburetion, which will cover throttle position, RPMs, tuning tricks, and alternative fuel systems like electronic fuel injection. During the intake cycle, the engine piston moves towards top dead center (TDC), creating a vacuum in the crankcase. Atmospheric pressure air behind the reed valve flows through the intake manifold, carburetor, flame arrestor, and engine compartment to equalize the pressure. A certain volume of air is ingested by the engine at a given power output, measured in cubic feet per minute (CFM). As this air travels through the intake tract, it may speed up or slow down to keep pace with the rest of the column. When the air passes through the carburetor venturi, it speeds up, causing a drop in pressure, known as the Bernoulli Principle. Carburetors use pressure differentials to move fuel from the fuel tank to the fuel pump, regulator chamber, fuel circuits, and carb bore. The fuel pump, powered by a hose vented into the crankcase, moves the diaphragm back and forth to draw fuel through the one-way check valve. The fuel in the chamber is pushed against the check valve and closes it. Fuel then passes through the needle and seat, which requires overcoming the spring pressure on the needle to open. The low-speed outlet, bypass holes, and high-speed outlet all receive fuel from the fuel chamber. The low-speed outlet operates when the throttle plate is almost closed, exposing it to the low pressure in the intake manifold. Fuel in the fuel chamber is at atmospheric pressure, so it flows through the low-speed jet, around the mixture screw, and out the outlet. In the next article, we'll discuss tuning tricks for adjusting the pop-off pressure of the needle valve, and explore the bypass holes and high-speed outlet for full throttle. The final article will explore alternative fuel systems such as electronic fuel injection and heavily modified carbs.

Bobby Boop Impellers.com I have a 1995 Kawasaki JS750 ZXI Jet Ski. The previous owner removed the oil injection system with Oil Pump Block Off Plate and mixed it the gas 40:1. I was wondering if it is worth it to put the oil pump back on? Or if it would be better for the machine. If not what is the best fuel ratio to run, and is there anything I should check to make sure the owner did everything right when he took off the oil system?Also, my machine doesn't seemed like it is as quick or fast as it should be. Is there anything else I should check, Like impeller or reeds.

Russ Russ, Reasons for removing oil pump is that Oil pumps can fail and You are able to pre-mix to a precise measurement as different oils offer different mixtures. I usually go 40:1 with standard oil and 50:1 with Synthetic oils. I would definitely check the Kawasaki impeller for nicks in the blades and the gap between the Jet Ski impeller and pump housing. If they have any issues that could defiantly cause a speed issue. Your ski is pretty old and I would recommend putting in some new reeds. I would do a head compression check and make sure all three cylinders are within 5lbs of each other. If they are more then 10psi between them you will need to do a rebuild top end piston kit. Ski Mechanic Tech Talk I have a 2002 Sea-Doo GTX DI, It ran perfectly, and then I winterized it, and, after taking it out of storage, it lost approximately 5 mph. The engine only gets to 4000 rpm until its been run across the lake, then it loosens up and reaches 5500rpm. weird. Do you have any ideas? Do the exhaust ports need to be cleaned every so often?

Chris Chris, Sea-Doo recommends annual cleaning of the RAVE valve guillotine to remove carbon build up. But a bad water regulator valve, low fuel pressure or a jet-pump problem can also cause this problem. Tech Talk I'm wondering if you can help me with winterizing my ski. I have heard to put fuel stabilizer in a full tank, partly full ect. Also make sure no water in system and put a bit of motor oil in each spark plug hole. Kind of a variety of efforts, and I'm wondering if you could help me in the correct way to winterize my jet ski?

Henry Hi Henry, When winterizing a ski, I put fuel stabilizer in a full tank of fuel and run the motor to make sure that the fuel stabilizer gets into the fuel system completely. Then while ski is running, pour antifreeze into cooling system until it comes out at the exhaust, then squirt fogging oil into the carburetor until the motor stalls. This whole operation should take about 30 minutes with no water hooked up. Then you remove the spark plugs and poor about an ounce of motor oil in each cylinder and turn the motor over to make sure that the oil coats fully. Then you should check the pump for water under the cap and re-seal the pump if it has been exposed to water. Then you should lubricate all fittings and moving parts (steer, trim ect..) Tech There is a difference in battery life between wet, sealed, gel and lithium batteries. A wet-cell battery is a good basic battery, but has its weaknesses. One problem is that these batteries are available in a wide range of quality, and price is not always the indicator of how good the battery actually is.

These batteries fail mainly from non use, which causes permanent damage in the form of sulfation. Some better quality wet batteries have a chemical additive to help prevent this problem,but eventually the battery will be damaged. The other main problem is lack of maintenance keep the electrolytes to the proper level with distilled water. sealed Batteries are usually high quality batteries but may have a lower amp capacity compared to wet or gel batteries.The high the amperage rating, the more cranking power you have. Lithium & Gel Batteries are the best quality being a "maintenance free" battery, they don't suffer when ignored as badly as a wet battery. Of course you pay the price for this convenience. Battery Chargers The Best battery charger I have found for maintaining is a battery tender. It can be left on the battery indefinitely without damaging the battery like a trickle charger. For charging your battery use a maximum of 3 amps. High amperage chargers will damage your battery. Tech Talk |

Details

Jet Ski & Boat Magazine - Your Ultimate Guide to Water AdventuresWelcome to Jet Ski & Boat Magazine E Zine, your go-to source for all things related to water sports and personal watercraft. Our E zine magazine is dedicated to providing you with the latest news, tips, and stories from the world of jet skiing, boating, and other exciting water activities. Categories

All

Archives

|

LOW PRICE Guarantee! We will meet or beat any advertised price!

|

|

We have the impeller edge on lowest prices, highest quality and performance impellers world wide

Personal Watercraft Jetski ATV Motorcycle Snowmobile SXS & Sport boat JetBoat Performance Since 1994

sportboatparts.com JetSkiParts.biz SportJetBoat.com

sportboatparts.com JetSkiParts.biz SportJetBoat.com

2024 Copyright Impellers.com

RSS Feed

RSS Feed